Maintaining optimal pH levels in your filtration system isn’t just a recommendation—it’s essential for ensuring peak performance, equipment longevity, and water quality that meets industry standards.

🎯 Why pH Monitoring Matters in Filtration Systems

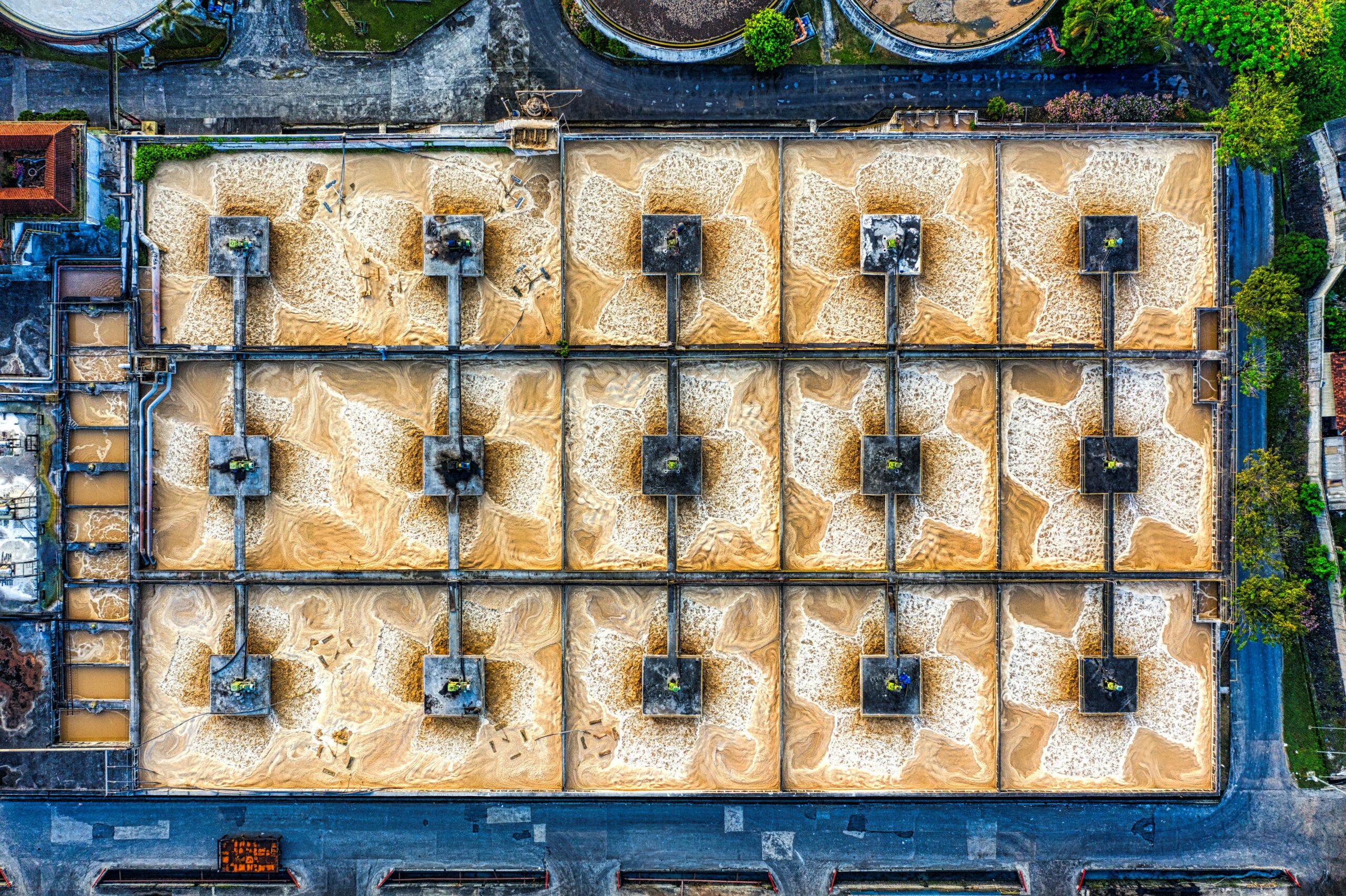

The pH level of water undergoing filtration can make or break your entire operation. Whether you’re managing a swimming pool, operating an industrial wastewater treatment facility, or maintaining an aquarium, pH drift during filtration cycles can compromise effectiveness, damage equipment, and create costly operational problems.

pH drift refers to the gradual change in pH levels that occurs as water moves through filtration media and equipment. This phenomenon happens due to chemical reactions, microbial activity, dissolution of minerals, and interactions between water and filtration components. Understanding and controlling this drift is fundamental to maintaining system efficiency.

When pH levels shift outside optimal ranges, several problematic scenarios emerge. Filtration media may lose effectiveness, chemical dosing becomes unreliable, equipment corrosion accelerates, and in some cases, regulatory compliance issues arise. The financial impact of ignoring pH drift can be substantial, affecting everything from maintenance costs to product quality.

⚗️ Understanding the Science Behind pH Drift

pH measures the concentration of hydrogen ions in a solution on a scale from 0 to 14, with 7 being neutral. Values below 7 indicate acidity, while values above 7 indicate alkalinity. During filtration, numerous factors conspire to alter these levels.

Primary Causes of pH Drift During Filtration

Carbon dioxide absorption or release represents one of the most common causes of pH change. As water moves through filtration systems, CO2 can be absorbed from the atmosphere or released from the water, directly impacting pH levels. This is particularly significant in open filtration systems or those with aeration components.

Filtration media itself can contribute to pH drift. Sand filters, activated carbon, and ion exchange resins all interact chemically with water. New filtration media often releases compounds that alter pH, while exhausted media may fail to maintain buffering capacity. Understanding your specific media’s impact on pH is crucial for predictive maintenance.

Biological activity within biofilters creates significant pH fluctuations. Nitrifying bacteria, for example, consume alkalinity and produce acid, lowering pH over time. In wastewater treatment, organic matter decomposition generates various acids that shift pH downward unless properly buffered.

Chemical dosing systems themselves can introduce pH variability. Coagulants, flocculants, and disinfectants all have pH impacts that must be accounted for in your monitoring strategy. The cumulative effect of multiple chemical additions requires sophisticated tracking and adjustment protocols.

📊 Establishing Your Baseline pH Parameters

Before you can effectively monitor pH drift, you must establish what “optimal” means for your specific application. Different filtration systems have vastly different ideal pH ranges based on their purpose and the water being treated.

| Application | Optimal pH Range | Critical Considerations |

|---|---|---|

| Swimming Pools | 7.2 – 7.8 | Chlorine effectiveness, user comfort |

| Drinking Water | 6.5 – 8.5 | Regulatory compliance, taste |

| Aquariums (Freshwater) | 6.5 – 7.5 | Species-specific requirements |

| Industrial Process Water | Varies widely | Process-specific optimization |

| Wastewater Treatment | 6.5 – 8.5 | Biological activity, discharge limits |

Once you’ve identified your target range, document the acceptable deviation limits. A swimming pool might tolerate 0.3 pH units of drift before requiring intervention, while a sensitive industrial process might demand corrections at 0.1 unit variations. These tolerance levels should be based on both operational requirements and regulatory standards.

🔍 Implementing Effective pH Monitoring Strategies

Continuous monitoring provides the most accurate picture of pH behavior throughout filtration cycles. Modern pH sensors and data logging equipment make real-time tracking practical and affordable for operations of all sizes.

Choosing the Right Monitoring Equipment

pH electrodes come in various configurations, from simple handheld meters to sophisticated inline sensors with automatic temperature compensation. For filtration systems, inline sensors offer distinct advantages—they provide continuous data without requiring manual sampling and eliminate human error from the monitoring process.

Sensor placement matters tremendously. Install sensors at strategic points throughout your filtration system: before filtration media, after filtration media, and at the final discharge point. This multi-point monitoring reveals where pH changes occur within your system, enabling targeted interventions rather than blanket adjustments.

Calibration schedules must be religiously maintained. Even the best pH sensors drift over time and require regular calibration with standard buffer solutions. Establish a calibration routine based on manufacturer recommendations and your operational criticality—weekly for critical systems, monthly for less sensitive applications.

Creating Your pH Monitoring Protocol

Develop a comprehensive monitoring protocol that includes measurement frequency, recording procedures, and action thresholds. During normal operations, hourly automated readings might suffice, but during backwash cycles or chemical additions, minute-by-minute monitoring may be necessary.

Document everything systematically. Modern data logging systems can automatically record pH values with timestamps, creating invaluable trend data. This historical information reveals patterns that might otherwise go unnoticed—seasonal variations, correlation with flow rates, or the gradual decline in media effectiveness.

Alert systems should notify operators when pH exceeds acceptable ranges. Automated alerts via text message, email, or dedicated monitoring apps ensure rapid response to pH drift events, minimizing the time your system operates outside optimal parameters.

💧 Recognizing pH Drift Patterns Throughout Filtration Cycles

Filtration cycles follow predictable patterns, and pH drift often exhibits characteristic behaviors during different cycle phases. Learning to recognize these patterns enables proactive rather than reactive management.

Startup Phase pH Behavior

When filtration systems first start after downtime, pH often experiences temporary instability. Stagnant water in filter vessels may have absorbed gases or leached compounds from media. The initial flush typically shows pH levels different from normal operation, sometimes varying by a full pH unit or more.

Document your system’s typical startup behavior to distinguish normal transient variations from problematic drift. Most systems stabilize within 15 to 30 minutes of operation, after which sustained deviations indicate issues requiring attention.

Steady-State Operation Drift

During continuous operation, pH should remain relatively stable within your established parameters. Gradual drift in one direction during steady-state operation signals developing problems—exhausted media, biological fouling, or inadequate buffering capacity.

Calculate your system’s drift rate by comparing pH measurements at fixed intervals during uninterrupted operation. A healthy system might show drift rates of 0.01-0.05 pH units per hour, while rates exceeding 0.1 units per hour typically indicate problems requiring investigation.

Backwash Cycle Considerations

Backwashing dramatically affects pH as accumulated materials are flushed from filtration media. pH often drops sharply as organic acids and other compounds are released. Monitor pH throughout the backwash cycle and into the rinse phase to ensure the system returns to baseline before resuming filtration.

Extended time to pH stabilization after backwashing suggests media degradation or inadequate rinse protocols. Track this recovery time as a key performance indicator for filter health.

🛠️ Correcting pH Drift: Practical Intervention Strategies

When monitoring reveals unacceptable pH drift, swift and appropriate corrections maintain system performance and prevent secondary problems from developing.

Chemical Adjustment Approaches

Acid and base dosing systems provide direct pH control. For low pH conditions, sodium carbonate (soda ash) or sodium bicarbonate offer safe, effective alkalinity. For high pH situations, carbon dioxide injection provides gentle, buffered pH reduction, while muriatic acid or sulfuric acid offer more aggressive correction.

Calculate dosing requirements carefully using water chemistry principles and your system volume. Start with conservative doses and monitor results before adding more chemicals. Overdosing creates rebound effects that may swing pH excessively in the opposite direction.

Automated dosing systems controlled by pH sensors provide the most consistent results. These systems continuously adjust chemical feed rates based on real-time pH readings, maintaining tight control without constant operator intervention.

Addressing Root Causes Rather Than Symptoms

While chemical adjustment addresses immediate pH problems, investigating underlying causes prevents recurring issues and reduces chemical consumption. If pH consistently drifts low during operation, examine potential causes: inadequate source water alkalinity, excessive biological acid production, or media that releases acidic compounds.

Media replacement schedules should reflect pH behavior. Filtration media loses buffering capacity over time, eventually becoming unable to maintain stable pH. Tracking pH stability provides an early warning that media replacement is approaching—often before traditional indicators like reduced flow rates or breakthrough become apparent.

📱 Leveraging Technology for Superior pH Management

Modern technology offers powerful tools for pH monitoring and management that were unimaginable just a decade ago. Cloud-connected sensors, smartphone apps, and data analytics platforms transform pH management from a reactive chore into a predictive science.

Smart sensors with IoT connectivity transmit data to cloud platforms where sophisticated algorithms identify trends, predict drift, and recommend interventions. These systems learn your specific operation’s patterns, becoming more accurate over time.

Mobile apps provide remote monitoring capabilities, allowing operators to check pH status from anywhere, receive alerts about excursions, and even adjust dosing systems remotely. This accessibility ensures rapid response regardless of operator location.

Data visualization tools transform raw pH measurements into actionable insights. Graphical displays reveal correlations between pH and other operational parameters—flow rates, temperature, chemical dosing, and more—illuminating cause-and-effect relationships that inform optimization strategies.

🎓 Training Your Team for pH Management Excellence

Technology and protocols are only effective when operators understand them and implement them consistently. Comprehensive training ensures your team can recognize pH problems, respond appropriately, and continuously improve system performance.

Education should cover fundamental water chemistry principles, not just button-pushing procedures. When operators understand why pH matters and how filtration affects it, they make better decisions in unexpected situations and contribute valuable observations to system optimization efforts.

Hands-on training with actual equipment builds confidence and competence. Practice sessions covering sensor calibration, data interpretation, and corrective actions prepare operators for real-world situations. Regular refresher training maintains skills and introduces new techniques as they develop.

Create detailed standard operating procedures that document every aspect of your pH monitoring program. These written procedures ensure consistency across shifts and serve as reference materials when questions arise during operations.

🌟 Advanced Optimization: Moving Beyond Basic Control

Once you’ve mastered fundamental pH monitoring and control, advanced optimization techniques can further enhance performance and efficiency. These strategies require more sophisticated analysis but deliver substantial operational benefits.

Predictive pH Management

Statistical analysis of historical pH data enables predictive maintenance approaches. By identifying patterns that precede pH drift events, you can implement preventive measures before problems actually occur. Machine learning algorithms excel at this pattern recognition, processing vast datasets to identify subtle indicators human operators might miss.

Seasonal variations in source water quality often affect pH behavior predictably. Document these patterns and adjust operational parameters proactively—increasing alkalinity dosing before the spring runoff period when acidic water typically arrives, for example.

Integrating pH Control With Broader System Management

pH doesn’t exist in isolation—it interacts with every other aspect of water chemistry and filtration performance. Holistic management approaches consider these interactions, optimizing multiple parameters simultaneously rather than treating each independently.

Coordinate pH management with oxidation-reduction potential (ORP) monitoring, turbidity measurement, and chemical residual tracking. This integrated approach reveals how adjustments in one parameter affect others, enabling more sophisticated optimization than single-parameter management allows.

💰 Calculating the ROI of Effective pH Monitoring

Investing in comprehensive pH monitoring systems and protocols delivers measurable financial returns that typically exceed costs within the first year of implementation.

Equipment longevity improves dramatically when pH remains within optimal ranges. Corrosion damage from acidic conditions or scaling from alkaline water causes thousands of dollars in premature equipment replacement and repairs. Maintaining proper pH extends the service life of pumps, valves, heat exchangers, and filtration vessels.

Chemical consumption decreases when pH is consistently controlled. Poorly managed pH requires excessive chemical additions to compensate for inefficiencies—chlorine consumption in pools increases dramatically at improper pH levels, for example. Optimized pH reduces these costs while improving treatment effectiveness.

Energy efficiency correlates with pH management in many systems. Pumps work harder pushing water through fouled or scaled filtration media, and heating/cooling systems lose efficiency when heat transfer surfaces are compromised by pH-related deposits. Maintaining optimal pH keeps systems running efficiently at design capacity.

Regulatory compliance costs plummet when pH is consistently maintained within acceptable ranges. Violations trigger fines, mandatory reporting, increased monitoring requirements, and potentially expensive remediation. Proactive pH management prevents these costly regulatory incidents.

🚀 Taking Action: Your pH Optimization Roadmap

Implementing or improving pH monitoring in your filtration system doesn’t require overwhelming changes made all at once. A systematic, phased approach achieves results while minimizing disruption to ongoing operations.

Begin with a comprehensive assessment of your current pH monitoring capabilities and challenges. Document existing equipment, protocols, and pain points. Identify where pH problems occur most frequently and what those problems cost in terms of chemical usage, equipment damage, and operator time.

Prioritize improvements based on impact and feasibility. Quick wins—like establishing consistent calibration schedules or installing sensors at critical monitoring points—build momentum and demonstrate value while you plan larger investments in automated systems or advanced analytics.

Set measurable goals for your pH optimization program. Define specific targets: reducing pH drift rates by a certain percentage, decreasing chemical consumption, extending time between media replacements, or achieving zero pH-related compliance violations. Measurable objectives enable progress tracking and justify continued investment.

Review and refine your approach continuously. pH management isn’t a set-it-and-forget-it proposition—seasonal changes, equipment aging, and operational modifications all affect optimal strategies. Regular reviews ensure your program evolves with changing conditions and incorporates emerging technologies.

The journey toward optimal pH management is ongoing, but the destination—reliable, efficient filtration delivering consistently high-quality water—is well worth the effort. By implementing rigorous monitoring, responding promptly to drift, and continuously optimizing your approach, you’ll achieve peak performance that protects your equipment, reduces costs, and ensures your filtration system operates at its absolute best. 💪

Toni Santos is a water systems analyst and ecological flow specialist dedicated to the study of water consumption patterns, closed-loop hydraulic systems, and the filtration processes that restore environmental balance. Through an interdisciplinary and data-focused lens, Toni investigates how communities can track, optimize, and neutralize their water impact — across infrastructure, ecosystems, and sustainable drainage networks. His work is grounded in a fascination with water not only as a resource, but as a carrier of systemic responsibility. From consumption-cycle tracking to hydro-loop optimization and neutrality filtration, Toni uncovers the analytical and operational tools through which societies can preserve their relationship with water sustainability and runoff control. With a background in hydrological modeling and environmental systems design, Toni blends quantitative analysis with infrastructure research to reveal how water systems can be managed to reduce waste, conserve flow, and encode ecological stewardship. As the creative mind behind pyrelvos, Toni curates illustrated water metrics, predictive hydro studies, and filtration interpretations that revive the deep systemic ties between consumption,循环, and regenerative water science. His work is a tribute to: The essential accountability of Consumption-Cycle Tracking Systems The circular efficiency of Hydro-Loop Optimization and Closed Systems The restorative capacity of Neutrality Filtration Processes The protective infrastructure of Runoff Mitigation and Drainage Networks Whether you're a water systems engineer, environmental planner, or curious advocate of regenerative hydrology, Toni invites you to explore the hidden flows of water stewardship — one cycle, one loop, one filter at a time.