Selecting the right pump for your system isn’t just about moving fluid—it’s about maximizing efficiency, reducing energy costs, and ensuring long-term reliability.

🔧 Understanding the Critical Role of Pumps in Loop Systems

Pumps serve as the heart of any closed-loop or open-loop system, circulating fluids through networks of pipes, heat exchangers, and equipment. Whether you’re managing an HVAC system, industrial cooling loop, or hydronic heating network, the pump you select directly impacts operational efficiency, maintenance requirements, and overall system performance.

The consequences of poor pump selection extend beyond immediate operational concerns. Oversized pumps waste energy through excessive flow rates and higher electrical consumption. Undersized pumps fail to meet system demands, causing temperature imbalances, inadequate cooling or heating, and premature equipment failure. The sweet spot lies in precise matching of pump characteristics to system requirements.

📊 Calculating Your System’s Fundamental Requirements

Before exploring pump options, you must thoroughly understand your system’s hydraulic requirements. Two primary factors determine pump selection: flow rate and total head.

Flow Rate Determination

Flow rate, typically measured in gallons per minute (GPM) or liters per second (L/s), represents the volume of fluid that must circulate through your system. Calculate this based on the thermal load your system must handle. For heating and cooling applications, use the formula:

Flow Rate (GPM) = (BTU/hr) / (500 × ΔT)

Where ΔT represents the temperature difference between supply and return lines. A larger temperature difference allows for lower flow rates, potentially enabling smaller, more efficient pumps. However, this must balance against heat exchanger effectiveness and system design constraints.

Total Head Calculation

Total head represents the total resistance your pump must overcome, measured in feet of head or meters of head. This includes friction losses through pipes, fittings, valves, heat exchangers, and any elevation changes. Accurate head calculation requires:

- Detailed pipe length measurements for all system segments

- Identification of all fittings, valves, and components

- Pressure drop specifications for equipment like heat exchangers

- Elevation changes between the highest and lowest points

- Safety margins for future expansion or fouling

Professional engineering software can streamline these calculations, but manual methods using friction loss charts remain viable for straightforward systems. Always add a 10-15% safety factor to account for uncertainties and future modifications.

⚙️ Exploring Pump Types for Different Applications

Not all pumps suit every application. Understanding the strengths and limitations of various pump types helps narrow your selection to the most appropriate options for your specific system requirements.

Centrifugal Pumps: The Workhorses of Loop Systems

Centrifugal pumps dominate closed-loop applications due to their reliability, efficiency, and relatively simple maintenance requirements. These pumps use rotating impellers to accelerate fluid radially outward, converting velocity into pressure. They excel in high-flow, moderate-head applications and offer several configurations:

End-suction pumps provide compact installations with the inlet and outlet at 90-degree angles. They’re cost-effective for smaller systems but may require more floor space and careful alignment during installation.

Inline pumps mount directly in the piping, with inlet and outlet on the same centerline. This configuration saves space and simplifies installation in cramped mechanical rooms. Many modern inline pumps feature integrated variable frequency drives for enhanced efficiency.

Split-case pumps handle larger flow rates with easier maintenance access. The horizontally split casing allows impeller inspection and replacement without disconnecting piping, reducing maintenance downtime for critical systems.

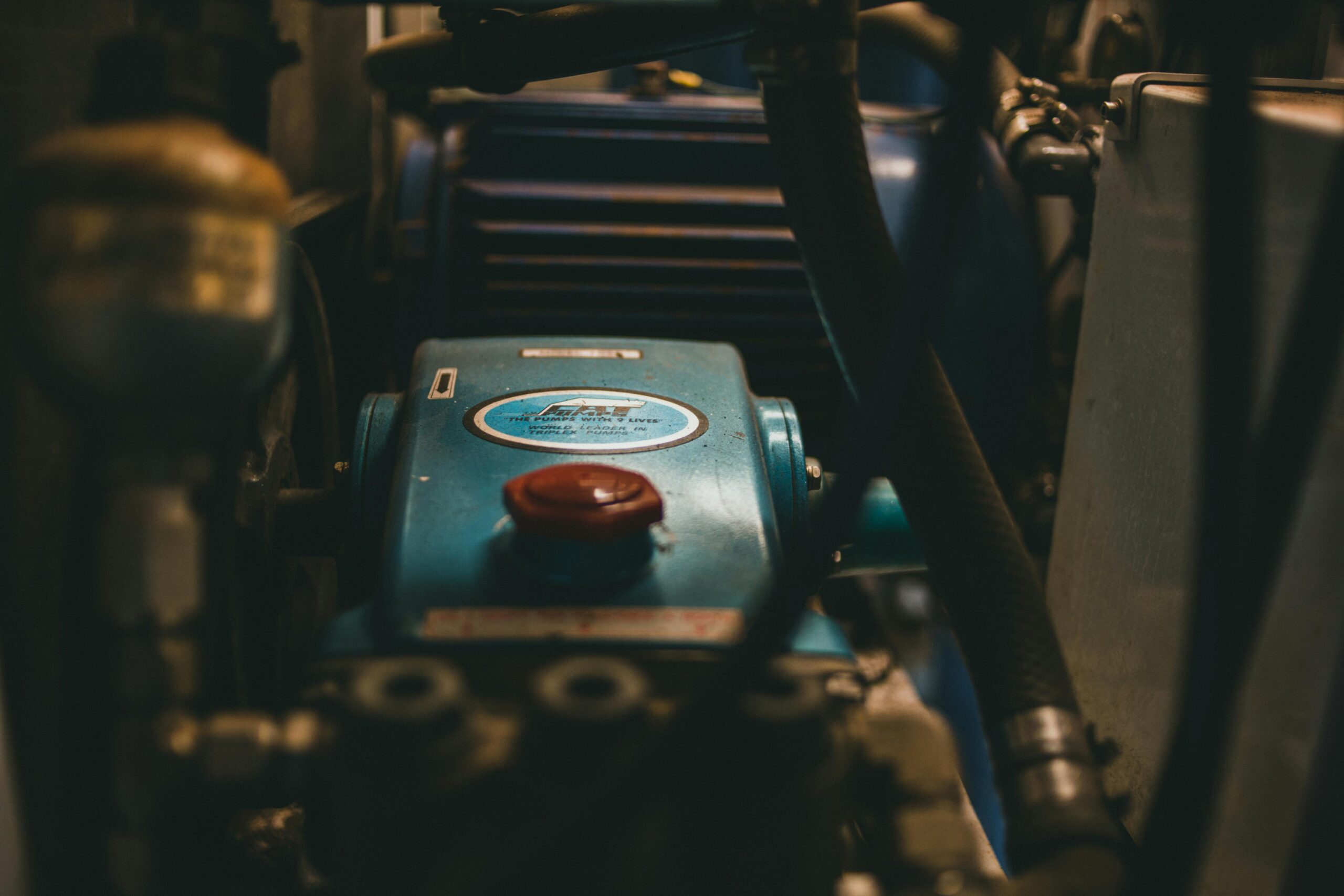

Positive Displacement Pumps for Specialized Needs

While less common in standard HVAC and hydronic loops, positive displacement pumps excel in specific scenarios requiring consistent flow regardless of system pressure variations. Gear pumps, lobe pumps, and progressive cavity pumps maintain steady flow rates even as viscosity changes or resistance increases.

These pumps suit applications involving viscous fluids, precise metering requirements, or situations where maintaining constant flow trumps energy efficiency concerns. However, they typically consume more energy than centrifugal alternatives for standard water-based systems.

💡 Efficiency Metrics That Actually Matter

Pump efficiency directly translates to operational costs over the equipment’s lifespan. A pump operating 8,760 hours annually can consume thousands or even tens of thousands of dollars in electricity. Understanding and prioritizing efficiency pays dividends throughout the system’s life.

Best Efficiency Point (BEP) Optimization

Every pump operates most efficiently at a specific combination of flow rate and head—the Best Efficiency Point. Operating far from BEP increases energy consumption, accelerates wear, and may cause operational issues like cavitation or excessive vibration.

Review pump curves carefully during selection. Choose pumps where your design operating point falls within 70-110% of BEP flow. Operating significantly to the left (low flow) or right (high flow) of BEP compromises efficiency and reliability. Modern pump manufacturers provide detailed performance curves showing efficiency islands across the operating range.

Part-Load Performance Considerations

Many systems don’t operate at peak design conditions continuously. Weather variations, occupancy changes, and production schedules create part-load conditions where thermal demands decrease. Traditional fixed-speed pumps perform poorly under these conditions, maintaining full flow even when unnecessary.

Variable frequency drives (VFDs) address this limitation by adjusting pump speed to match actual system requirements. The affinity laws demonstrate the dramatic energy savings potential: halving pump speed reduces flow by 50%, head by 75%, and power consumption by 87.5%. In systems with significant part-load operation, VFDs typically achieve payback periods under three years.

🎯 Advanced Selection Strategies for Maximum Performance

Beyond basic flow and head matching, several advanced considerations separate adequate pump selection from optimized system design.

System Curve Analysis

Your system possesses a characteristic resistance curve relating flow rate to required head. This system curve intersects the pump curve at the operating point. Understanding this relationship reveals several critical insights:

Parallel pump arrangements shift the combined pump curve rightward, increasing available flow while maintaining the same head at any given point. This configuration suits systems requiring redundancy or variable capacity, though careful control prevents pumps from fighting each other.

Series pump arrangements shift the combined curve upward, increasing available head while maintaining the same flow. While less common in HVAC applications, series configurations address situations where single pumps cannot generate sufficient pressure.

Net Positive Suction Head (NPSH) Requirements

Cavitation destroys pumps rapidly, creating noise, vibration, and physical damage to impellers and casings. Preventing cavitation requires ensuring available NPSH exceeds required NPSH with adequate margin.

Calculate NPSH available by considering atmospheric pressure, static elevation differences, fluid vapor pressure, and suction line losses. Compare this against the pump manufacturer’s NPSH required specification. Maintain at least a 3-foot safety margin, more for critical applications or systems handling fluids near their boiling points.

Material Selection for Longevity

Pump materials must withstand the chemical composition, temperature, and abrasiveness of your system fluid. Standard cast iron pumps suit most closed-loop glycol and water systems, offering durability at reasonable cost. However, specialized applications demand alternative materials:

- Bronze or stainless steel for corrosive fluids or open systems

- All-stainless construction for pharmaceutical or food-grade applications

- Special coatings or linings for aggressive chemical environments

- Composite materials for ultra-pure water systems preventing metallic contamination

🔍 Evaluating Total Cost of Ownership

Initial purchase price represents only a fraction of true pump ownership costs. Comprehensive evaluation considers energy consumption, maintenance requirements, reliability, and expected lifespan.

Energy Cost Analysis

Calculate annual energy consumption using the formula:

Annual kWh = (GPM × Head × 0.746) / (3960 × Efficiency × Motor Efficiency) × Operating Hours

Multiply by your local electricity rate to determine annual energy costs. A pump operating 6,000 hours annually with a 3-point efficiency advantage saves substantial money over its lifespan. When comparing options, calculate the present value of energy savings over the expected equipment life—typically 15-20 years for quality pumps.

Maintenance Accessibility and Requirements

Pumps requiring frequent maintenance or specialized service increase ownership costs through labor, parts, and downtime. Consider these factors:

Mechanical seal design significantly impacts maintenance frequency. Standard packing requires periodic adjustment and replacement, while mechanical seals offer superior reliability with minimal attention. Advanced cartridge seals simplify replacement, reducing labor requirements when service becomes necessary.

Bearing design affects both reliability and maintenance complexity. Permanently lubricated bearings eliminate routine greasing, though they’re not replaceable. Grease-fitting bearings require periodic lubrication but allow bearing replacement without complete pump disassembly.

Coupling arrangements between pump and motor influence alignment requirements and maintenance access. Close-coupled designs eliminate the coupling entirely, reducing maintenance but requiring complete assembly replacement if either component fails. Frame-mounted designs with flexible couplings allow independent motor or pump replacement.

🌐 Smart Controls and Monitoring Technologies

Modern pump systems increasingly incorporate sophisticated controls and monitoring capabilities that enhance efficiency and reliability while reducing operational intervention.

Integrated VFD Benefits Beyond Energy Savings

Variable frequency drives offer advantages extending beyond reduced energy consumption. Soft-start capabilities eliminate water hammer and mechanical stress during startup, extending equipment life. Programmable ramping prevents abrupt flow changes that challenge system components and controls.

Many VFDs include built-in energy monitoring, tracking power consumption, operating hours, and efficiency metrics. This data enables informed maintenance decisions and helps identify developing problems before they cause failures. Advanced drives communicate via standard building automation protocols, integrating seamlessly into comprehensive facility management systems.

Predictive Maintenance Through Continuous Monitoring

Sensors monitoring vibration, temperature, flow rate, and power consumption detect developing issues early. Bearing wear, impeller damage, and seal degradation create characteristic signatures recognizable through trending analysis. Addressing problems during planned maintenance windows prevents catastrophic failures and costly emergency repairs.

Wireless monitoring systems simplify retrofit installations, eliminating expensive conduit runs while providing real-time data to maintenance teams. Cloud-based analytics platforms identify patterns across multiple installations, applying machine learning to predict failures with increasing accuracy.

🛠️ Installation Best Practices for Optimal Performance

Even perfectly selected pumps underperform when improperly installed. Following proven installation practices ensures your equipment delivers expected performance and longevity.

Pipe Configuration Guidelines

Provide adequate straight pipe runs before and after the pump—typically 5-10 pipe diameters on the suction side and 2-3 diameters on the discharge. These straight sections ensure developed flow profiles entering the pump, preventing cavitation and vibration issues.

Install suction piping with slight upward slopes toward the pump, preventing air pocket accumulation. Keep suction lines as short as practical, minimizing friction losses that reduce available NPSH. Avoid reducer fittings immediately before the pump inlet; eccentric reducers positioned at least two pipe diameters upstream prevent flow disturbances.

Vibration Isolation and Structural Support

Pump vibration transmits through rigid connections into building structures, creating noise issues and potentially damaging pipes and equipment. Spring isolators or isolation pads interrupt vibration transmission while maintaining proper pump alignment.

Ensure pump mounting surfaces provide rigid, level support. Concrete housekeeping pads or structural steel frames prevent deflection under operating loads. Check and maintain proper alignment between pump and motor couplings—misalignment accelerates bearing wear and creates unnecessary vibration.

⚡ Troubleshooting Common Performance Issues

Understanding typical problems and their solutions helps maintain optimal system performance throughout the equipment lifecycle.

Addressing Insufficient Flow or Pressure

When systems fail to deliver expected performance, systematic diagnosis identifies root causes. Check that all isolation valves remain fully open—partially closed valves dramatically increase system resistance. Verify that strainers haven’t accumulated debris, restricting flow and increasing pressure drop.

Impeller wear or damage reduces pump capacity over time. Compare current performance against original pump curves; significant degradation indicates internal wear requiring service. Air entrainment also compromises performance—bleed air from system high points and verify expansion tank pre-charge pressure maintains proper system pressurization.

Resolving Cavitation and Noise Issues

Cavitation creates distinctive rattling or gravel-like sounds and causes rapid component deterioration. Verify adequate NPSH by checking system pressurization, confirming expansion tank function, and ensuring suction line sizing and routing minimize friction losses. Reduce pump speed if possible, lowering required NPSH and potentially resolving cavitation without system modifications.

Some noise stems from flow-induced pipe vibration rather than pump issues. Check for inadequate pipe support allowing resonance, and verify that flow velocities remain within recommended ranges—typically 4-8 feet per second for closed-loop systems.

🎓 Future-Proofing Your Pump Selection

Smart pump selection considers not only current requirements but also probable future needs and evolving technologies.

Design systems with 10-20% capacity margins accommodating reasonable expansion without complete equipment replacement. Modular approaches using multiple smaller pumps rather than single large units provide inherent redundancy while allowing incremental capacity increases.

Select equipment compatible with emerging communication protocols and control strategies. Pumps with standard BACnet, Modbus, or similar connectivity integrate smoothly into sophisticated building management systems, enabling optimization strategies impossible with isolated equipment.

Consider sustainability beyond energy efficiency. Pumps designed for long service lives, using recyclable materials and supporting component-level repairs rather than complete replacement, align with circular economy principles increasingly valued by facility owners and operators.

🚀 Maximizing Your Investment Through Proper Selection

Mastering pump selection transforms this critical equipment choice from a necessary specification task into an opportunity for system optimization. The most efficient, reliable, and cost-effective systems result from thorough analysis, careful matching of equipment to requirements, and attention to installation and operational details.

Energy costs alone justify the additional effort required for optimal pump selection. A system operating inefficiently for 15-20 years wastes thousands or tens of thousands of dollars while delivering compromised performance. The improved comfort, reliability, and reduced maintenance accompanying proper selection provide additional returns beyond direct energy savings.

Your system deserves pumps matched precisely to its requirements—equipment operating at peak efficiency, maintaining reliable performance throughout its service life, and supporting rather than constraining your operational objectives. Investment in comprehensive pump selection analysis pays dividends from commissioning through eventual replacement, powering optimal loop efficiency every day of system operation.

Toni Santos is a water systems analyst and ecological flow specialist dedicated to the study of water consumption patterns, closed-loop hydraulic systems, and the filtration processes that restore environmental balance. Through an interdisciplinary and data-focused lens, Toni investigates how communities can track, optimize, and neutralize their water impact — across infrastructure, ecosystems, and sustainable drainage networks. His work is grounded in a fascination with water not only as a resource, but as a carrier of systemic responsibility. From consumption-cycle tracking to hydro-loop optimization and neutrality filtration, Toni uncovers the analytical and operational tools through which societies can preserve their relationship with water sustainability and runoff control. With a background in hydrological modeling and environmental systems design, Toni blends quantitative analysis with infrastructure research to reveal how water systems can be managed to reduce waste, conserve flow, and encode ecological stewardship. As the creative mind behind pyrelvos, Toni curates illustrated water metrics, predictive hydro studies, and filtration interpretations that revive the deep systemic ties between consumption,循环, and regenerative water science. His work is a tribute to: The essential accountability of Consumption-Cycle Tracking Systems The circular efficiency of Hydro-Loop Optimization and Closed Systems The restorative capacity of Neutrality Filtration Processes The protective infrastructure of Runoff Mitigation and Drainage Networks Whether you're a water systems engineer, environmental planner, or curious advocate of regenerative hydrology, Toni invites you to explore the hidden flows of water stewardship — one cycle, one loop, one filter at a time.